Ebb-and-Flow Bioreactor

Regime and Electrical

Elicitation: Novel

Strategies for Hairy Root

Biochemical Production

Joel L. Cuello and Lisa C. Yue

The University of

Arizona, Department of Agricultural and Biosystems Engineering,

507 Shantz Building, Tucson, AZ

*Corresponding author; email:

cuelloj@mail.arizona.edu

Keywords:

ebb-and-flow bioreactor, hairy roots, electrical elicitation

ABSTRACT

The ebb-and-flow

bioreactor regime and electrical elicitation constitute two

novel and promising effective strategies for realizing the

large-scale production of secondary metabolites from hairy roots

growing in scaled-up bioreactors. Employing the ebb-and-flow

regime would provide the forced-convective action that is needed

to overcome the mass-transfer resistances offered by the

stagnant external boundary layers and/or dead zones which

normally exist in the high-density hairy-root bioreactor

environment – both in liquid-phase and in gas-phase bioreactors.

Meanwhile, employing electrical elicitation could significantly

overproduce valuable secondary metabolites produced by hairy

roots. Combining the two strategies could certainly help achieve

the economic feasibility of the large-scale production from

plant hairy roots of specific secondary metabolites.

INTRODUCTION

Plant roots have long been known as prolific manufacturers of an

assortment of economically important chemicals. Since Dawson

(1942) first showed conclusively that the roots of Nicotiana

tabacum were the site of synthesis of the secondary

metabolite nicotine, numerous root cultures representing a wide

range of species have been demonstrated to produce diverse kinds

of phytochemicals in vitro. The advent of transgenic

hairy roots has presented a novel and versatile system for

production of plant chemicals (Kamada et al., 1986; Flores et

al., 1993; Mahagamasekera and Doran 1998; Medina-Bolivar et al.,

2007) and even of transgenic proteins (Medina-Bolivar et al.,

2003; Medina-Bolivar and Cramer 2004). Hairy roots have a

typical doubling time in culture of 2 to 4 days, grow

significantly faster than untransformed roots, are stable in

culture, grow significantly faster than most suspension cell

cultures, and generally produce the same if not higher levels of

metabolites as do normal roots and cell suspension cultures

(Hamill et al., 1987; Flores et al., 1987; Kwok and Doran 1995).

This paper describes the ebb-and-flow bioreactor regime as a

novel and promising effective strategy for overcoming the

scale-up challenges that stand in the way of realizing the

large-scale production of desired phytochemicals from

immobilized hairy root cultures growing in bioreactors. This

work also describes electrical elicitation as a novel and

promising effective strategy for significantly increasing the

production of secondary metabolites by hairy roots in

large-scale bioreactors.

EBB-AND-FLOW BIOREACTOR

REGIME

Hairy Root Bioreactor

Challenges

The mass production of chemicals derived from hairy roots

requires the development of scaleable hairy root bioreactors.

However, the tangled and fibrous-clump morphology which the

hairy roots assume under high-density conditions in bioreactors

which is conducive to creating external boundary layers over

root surfaces and around the root clumps and stagnant zones

within the root clumps presents significant mixing and

mass-transfer challenges for liquid-based delivery of nutrients

and oxygen to the roots. Oxygen's low solubility in aqueous

medium and its poor mass transfer through the medium into the

root cells simply make O2 the most critical limiting

factor in hairy root bioreactor design (Yu and Doran 1994;

Ramakrishnan and Curtis 1995; Kanokwaree and Doran 1997;

Tescione et al., 1997).

In general, a hairy root bioreactor has to fulfill four minimum

requirements upon scale up (Cuello 1994): (1) its characteristic

configuration (e.g., flow configuration, geometric

configuration, etc.) must remain operative, and not degrade,

upon scale up; (2) it should make the nutrients and oxygen

available, or accessible, to the roots throughout the reaction

volume; (3) it should supply both nutrients and oxygen to the

roots in sufficient concentrations throughout the reaction

volume; and (4) it should lend itself to the scale up process by

possessing identifiable and quantifiable characteristic process

parameters which can be duplicated at larger scales with

relative ease and economy.

Various configurations for small-scale hairy root bioreactors

have been employed since the mid 1980’s. Rhodes et al., (1986)

were the first to demonstrate the successful growth of a hairy

root culture in a bioreactor for pharmaceutical production, and

were also first to employ a submerged convective-flow

configuration in a root bioreactor, growing Nicotiana rustica

hairy root culture in an 880 mL continuous convective flow

bioreactor (CFR). Seminal studies on other types of hairy root

bioreactor configuration were conducted by: (1) Taya et al.,

(1989) for bubble column, immobilized bubble column, immobilized

trickle-bed column and immobilized fill-drain (ebb-and-flow)

column bioreactors; (2) Kondo et al., (1989) for turbine-blade,

rotating-drum and immobilized rotating-drum bioreactors; (3)

Hilton and Rhodes (1990) for modified batch and continuous

stirred-tank bioreactors; and, (4) DiIorio et al., (1992) for a

nutrient mist bioreactor. Cuello et al., (1991) were the first

to demonstrate the successful growth of a hairy root culture in

an ebb-and-flow bioreactor. Subsequent studies on hairy root

bioreactors were reviewed by Singh and Curtis (1994) and Choi et

al., (2006), among others.

Of the foregoing hairy root bioreactor configurations, only a

few can be expected in theory to sustain the successful growth

of high-density hairy root cultures upon scale up to

significantly larger volumes. For a simple bubble-column design,

the dense packing of root clumps would promote bubble coalescing

and channeling, leading to poor liquid mixing, localized liquid

stagnation and, ultimately, to severe oxygen and nutrient

maldistributions and limitations. A fine-mist configuration

would be expected to break down into a trickle-bed configuration

along the length of the bioreactor, since fine mists would not

remain as such after they enter into the dense root bed (Flores

and Curtis 1991). Although the trickle-bed configuration appears

to be scaleable, it has the potential problem of being

susceptible to liquid channeling and liquid stagnation. A

stirred-tank bioreactor, with the roots immobilized and securely

removed from the impeller zone, would likely have problems of

liquid stagnation along the reactor periphery. Meanwhile, a

horizontal rotating drum bioreactor appears to have scale-up

potential. With the drum partially filled with liquid medium,

its immobilized roots would be exposed to alternating gas and

liquid phases. This design, however, is complicated by the

gradient in linear velocities experienced by the roots along the

radius of the reactor.

The continuous CFR and the ebb-and-flow bioreactor (EFBR), both

exhibiting saturated tubular convective flow part of the time in

the case of the EFBR possess the advantage of liquid and gas

mixing through the root matrix, which can be maintained upon

scale up. Being continuous systems (with inflow and outflow),

both are also ideal configurations for the following scenarios:

(1) when the roots require separate biomass accumulation stage

and secondary-metabolite production stage, requiring a change in

nutrient medium during the course of the growth period; (2) when

the concentration of dissolved oxygen in the liquid medium needs

to be brought back periodically to a certain level, requiring

re-aeration of the liquid medium in a separate well-mixed

reservoir; and (3) when the extracellular secondary metabolites

excreted by the roots into the liquid medium need to be

continually extracted from the liquid medium through in situ

product removal (ISPR) to prevent feedback inhibition. Both the

CFR and EFBR, however, would be expected to have critical limits

in their heights to prevent the dissolved-oxygen concentrations

in the bulk liquid from becoming growth-limiting to the roots.

The EFBR has the following three principal advantages over the

CFR: (1) expected better mixing and mass-transfer capacities

owing to the recurrent back-and-forth liquid flows and

intermittent liquid and gas phases; (2)

intermittent exposures to gas phase, allowing for more

effective manipulation of the gas composition (e.g., possible

addition or removal of certain gases such as oxygen, carbon

dioxide or ethylene) for further optimization of root growth or

phytochemical production; and (3) the ability to alleviate the

significant energy penalty imposed by the high pressure drop

created by the dense root bed by simply flooding the roots with

the nutrient medium during the Fill Time (i.e., during the flow

phase of the ebb-and-flow regime) and letting the nutrient

medium drain out of the root bed by gravity or as assisted by a

pump during the Drain Time (i.e., during the ebb phase of the

ebb-and-flow regime). In contrast, a CFR requires that its

liquid nutrient medium be pushed in bulk through the root bed

continuously, incurring the full energy penalty of the root

bed’s high pressure drop during the entire bioreactor run.

The Ebb-and-Flow

Bioreactor

The ebb-and-flow bioreactor derives its name from the process

behavior of its liquid medium which is characterized by its

repetitive ebbing and flowing or periodic filling and draining

(Figure 1). The reactor may be considered as the common-sense

compromise between the two extreme bioreactor configurations of

the predominantly liquid-phase and the predominantly gas-phase.

The ebb-and-flow bioreactor has four characteristic operational

phases which recur sequentially and intermittently as the liquid

medium moves back and forth between the bioreactor vessel and

its reservoir (Figure 2). These include the liquid dwell time

(LDT), the drain time (DT), the gas dwell time (GDT) and the

fill time (FT). The LDT is the phase where the whole reaction

volume of the EFBR is completely submerged in liquid, and where

the bulk of the liquid medium is neither flowing upward nor

downward. The GDT is that operational phase where the EFBR

reaction volume is predominantly in the gas phase, and where

mass flow of the bulk liquid medium is not occurring. The

operational phases where the bulk flow of the liquid medium

takes place are the FT, when the bulk flow direction is upward,

and the DT, when the bulk flow direction is downward.

Figure 1.

Schematic of an ebb-and-flow bioreactor, showing the bioreactor

vessel containing the hairy roots and a programmable reversible

pump that moves the liquid nutrient solution back-and-forth

between the bioreactor vessel and the reservoir. Compressed air

is sparged through the bottom of the bioreactor vessel.

Figure 2.

The four characteristic operational phases of the ebb-and-flow

bioreactor which recur sequentially and intermittently as the

liquid medium moves back and forth between the bioreactor vessel

and its reservoir. FT = fill time, LDT = liquid dwell time, DT =

drain time and GDT = gas dwell time. Both x and y axes are time

scales. The direction of the arrows pertains to process flow.

Ebb-and-Flow Bioreactor Vs. Bubble Column

Cuello et al. (2003a, 2003b) compared the growth performance of

a 2.5-L EFBR (Figure 3) against that of a bubble column, also

called a submerged sparged bioreactor (SSBR). The EFBR was

operated with the following values of operational parameters:

LDT = 2 min; GDT = 2 min; FT = 1 min; and DT = 1 min. It was

operated in two stages: first, under a bubble column regime for

the first seven days of growth; and, second, under the

fill-and-drain process for the succeeding time period. The

normal EFBR treatment was sparged at an air flow rate of 2.72

mL/s, equivalent to 0.115 vvm, during the entire growth

duration. At the start of the reactor run, the EFBR vessel

contained 2000 mL of liquid medium while the reservoir contained

500 mL. Note that the working volume inside the bioreactor

vessel was only 2000 mL.

Three types of controls were used in discriminating the effects

of the ebb-and-flow process. These controls included: (1) the

Erlenmeyer shake flasks; (2) a recirculating SSBR; and (3) a

nonrecirculating SSBR. The shake flasks used were of two sizes:

the 125 mL size and the 1000 mL size containing 50 mL and 250 mL

of liquid medium, respectively. The rationale for using a

recirculating SSBR control was to keep the total volume of the

liquid medium for this control the same as that for the EFBR

treatment which was 2500 mL. Similar to the EFBR, the

recirculating SSBR contained 2000 mL of liquid medium in the

bioreactor vessel and 500 mL in its reservoir at the beginning

of a reactor run. Operated as a bubble column with the same

sparging rate as the EFBR for the first seven days, the

recirculating SSBR was then operated starting on the eighth day

so that its liquid medium was recirculated between its cylinder

and reservoir at a rate averaging 0.5 mL s-1, a flow

rate that was significantly lower than that of the EFBR. During

the FT and DT operational phases of the EFBR, the flow reached

its minimum value at an average of 14.4 mL s-1 on day

18. The third control, a nonrecirculating SSBR which contained

only 2000 mL of liquid medium in its cylinder (it had no

reservoir), was somewhat of a control for the recirculating SSBR

to demonstrate that any effects of the low convective flow

produced by the recirculation of liquid medium were negligible.

The 125 mL flask control was referred to as 50 mL flask control,

the 1000 mL flask as 250 mL flask control, the recirculating

SSBR as SSBR, and the nonrecirculating SSBR as SSBRnonrec.

The results by Cuello et al., (2003b) clearly demonstrated the

EFBR’s successful scale up of the 50 mL flask to a 50X scale.

The 2.5 L EFBR produced an average dry weight of 21.64 g in 18 d

(Figure 3) which was statistically indistinguishable from the

combined average dry weights after 18 d of fifty 50 mL shake

flasks of 23 g, at

a = 0.05, and of ten

250 mL shake flasks of 20.3 g, also at

a

= 0.05. Note that these comparisons were based on an equal total

volume of the liquid medium, 2500 mL. By contrast, the combined

average dry weights for the 250-mL flasks significantly fell

short (a

= 0.05) of those for the 50 mL flasks, showing the failure of

the Erlenmeyer flask to be amenable to the scale-up process.

Figure 3.

Growth comparison of Hyoscyamus muticus hairy root

cultures after 18 days in bioreactors with 2500 mL of B5 medium;

n = number of observations. EFBR = ebb-and-flow bioreactor; SSBR

= submerged sparged bioreactor; LDT = EFBR with LDT of 5 min;

GDT = EFBR with GDT of 8 min.

Comparing the EFBR against the SSBR, the EFBR's average dry

weight significantly exceeded by 138% (a = 0.05) that for

the SSBR of 9.08 g. It was noteworthy that there was no

significant difference (a

= 0.05) between the average dry weight of 7.56 g for the SSBRnonrec

and that for the SSBR, indicating that the SSBR indeed had

negligible convective flow and that it was the back-and-forth

convective flow of the EFBR that made it superior to the SSBR.

It also showed that air bubbling, which was present in both EFBR

and SSBR, was by itself insufficient to maintain root growth at

larger scale.

The bioreactors' average specific growth rates (Table 1)

reflected the same trends exhibited by their dry weights. No

significant statistical differences existed between the average

specific growth rates of the EFBR (0.211 d-1) and the

two shake-flask controls (0.218 d-1 for 50 mL flask

and 0.217 d-1 for 250 mL flask, both at

a

= 0.05), but the average specific growth rate of the EFBR

significantly exceeded by 41% (a

= 0.04) that of the SSBR (0.150 d-1). Also, the

average specific growth rate of the SSBR was not

significantly different (a

= 0.05) from that of the SSBRnonrec (0.142 d-1).

Table 1.

Comparison of average specific growth rates (μ) of Hyoscyamus

muticus hairy root cultures grown in different bioreactor

treatments for 18 days; n = number of observations. EFBR =

ebb-and-flow bioreactor; SSBR = submerged sparged bioreactor;

LDT = EFBR with LDT of 5 min; GDT = EFBR with GDT of 8 min.

|

Treatment |

(day-1) |

n |

|

50 mL flask |

0.219 ± 0.004 |

29 |

|

250 mL flask |

0.217 ± 0.0000 |

3 |

|

EFBR |

0.211 ± 0.016 |

3 |

|

SSBR |

0.150 ± 0.026 |

3 |

|

SSBRnonrec |

0.142 ± 0.001 |

2 |

|

LDT |

0.188 ± 0.001 |

2 |

|

GDT |

0.181 ± 0.004 |

2 |

Cuello et al., (2003b) found that the EFBR and the SSBR growth

profiles over time did not exhibit a marked divergence in their

daily dry weights until after day 14. The subsequent rapid

increase in the dry weight of the EFBR distinctly contrasted

with the smaller growth increments exhibited by the SSBR. This

result was supported by visual observations. No appreciable

differences were observed between the roots growing in the EFBR

and those in the SSBR controls until after the first 10 d of

their growth period. It was then when the roots in the EFBR as

well as in the SSBR controls started developing into discrete

root clumps, which continued to grow and expand and, by day 14,

eventually interlocked with neighboring root masses to form a

tangled, porous matrix of fibrous hairy roots. At this time,

significant coalescing and channeling of the sparged air bubbles

during the liquid-phase duration were observed, suggesting the

formation of localized stagnant regions within the root clumps

as well as the formation of significant external boundary

layers. It was also at this time when the difference between the

EFBR and the SSBR controls in terms of both growth rate and

accumulated biomass sharpened significantly.

Comparing the SSBR and the EFBR hold-up profiles upon drainage

(Figure 4), Cuello et al., (2003b) found that the residual

hold-up for the SSBR progressively declined after successive

draining of its liquid medium. By contrast, the residual hold-up

for the EFBR after successive draining remained essentially

constant. While the EFBR consistently held up approximately the

same volume of medium after each time that the bulk liquid was

drained, the SSBR exhibited time-dependency in its residual hold

up, with diminishing hold-up levels upon drainage repetition.

After repeated filling and draining, the residual hold-up of the

SSBR continually decreased and approached that of the EFBR.

These results indicated that, in comparison with the EFBR, the

SSBR possessed significantly more external boundary layers

around the roots and/or stagnant zones that provided significant

resistance to mass transfer of oxygen and nutrients. Meanwhile,

the bi-directionality of the forced convective flow in the EFBR

and the repetitive filling and draining of its bulk medium

successfully ensured the periodic attenuation of both the

boundary layers and any stagnant zones within the EFBR. The

sugar profiles for the EFBR and the SSBR showed that, on day 18,

the total sugar level in the EFBR was 8.9 g L-1, a

level that was considerably lower than that in the SSBR of 14.0

g L-1 for the same day. This result confirmed that

the SSBR control, relative to the EFBR, was hampered by sugar

mass-transfer limitation. And given the much lower solubility of

oxygen in the liquid medium, and the finding that the oxygen

consumption rate in the EFBR and SSBR remained statistically the

same at an average value of 0.05 mg min-1 g-1

DW, it could safely be inferred that the SSBR was also hampered

by oxygen mass-transfer limitation. The foregoing results on the

poor growth performance of the SSBR and the accompanying

observations about its hydrodynamic behavior are consistent with

those reported by others (Shia and Doran 2000; Kanokwaree and

Doran 2000).

Figure 4.

Time profiles of residual hold-up for normal ebb-and-flow

bioreactor (EFBR) treatment and submerged sparged bioreactor

(SSBR) growing Hyoscyamus muticus hairy roots at tissue

concentrations of 267 and 283 g L-1 FW, respectively.

Profiles obtained on successive drainage are designated by 1,

2, etc., in chronological order.

EFBR with Prolonged Liquid

Phase and EFBR with Prolonged Gas Phase

Cuello et al., (2003b) also ran an EFBR treatment with a

prolonged liquid phase, called LDT treatment, whose LDT = 5 min,

GDT = 2 min, FT = 1 min and DT = 1 min. Likewise, an EFBR

treatment with a prolonged gas phase, called GDT treatment,

whose GDT = 8 min, LDT = 2 min, FT = 1 min and DT = 1 min, was

also performed.

Their results (Figure 3) showed that the LDT treatment's average

dry weight of 14.99 g and the GDT treatment's average dry weight

of 12.74 g fell between those of the EFBR and the SSBR control,

that is, below that of the EFBR and above that of the SSBR

control. Although the average dry weights of the LDT and GDT

treatments remained statistically indistinguishable from that of

the normal EFBR treatment, both at

a

= 0.05, the average dry weights of the LDT and the GDT

treatments were nonetheless 31% and 41% lower than that of the

normal EFBR treatment, respectively. Indeed the average dry

weights of the LDT and the GDT treatments became significantly

lower than that of the normal EFBR treatment at

a

= 0.12 and

a

= 0.06, respectively. Equally noteworthy, the average dry

weights of both the LDT and the GDT treatments were

significantly lower (a

£ 0.05) than those of

the 50 mL and the 250 mL shake-flask controls. At the opposite

lower end, though the average dry weights of the LDT and GDT

treatments remained statistically indistinguishable from that of

the SSBR, both at

a

= 0.05, the average dry weights of the LDT and the GDT

treatments nonetheless exceeded that of the SSBR by 65% and 40%,

respectively. These same trends were exhibited by the resulting

growth rates (Table 1).

The sugar profiles showed that, on day 18, the total sugar

levels in the LDT and GDT treatments hovered over 8.9 g L-1,

a level that was the same as that for the normal EFBR and again

considerably lower than that in the SSBR control of 14.0 g L-1

for the same day. These results showed that the sugars in the

GDT and LDT treatments were consumed to the same extent as that

in the normal EFBR treatment, indicating that, just as the

normal EFBR treatment did not suffer from sugar mass-transfer

limitation, neither the LDT treatment nor the GDT treatment also

suffered from sugar mass-transfer limitation. Otherwise, the

final sugar concentrations of the LDT and GDT treatments would

have been closer to the SSBR’s higher residual sugar

concentration of 14.0 g L-1.

Despite the LDT and the GDT treatments not experiencing

significant sugar mass-transfer limitations, however, the

dry-weight and growth-rate results (Figure 1 and Table 1)

indicated that the growth performances of both the LDT and GDT

treatments were on the verge of becoming significantly poorer

than that of the normal EFBR treatment. And, indeed, the average

dry weights of both the LDT and the GDT treatments were

significantly poorer than those of the 50 mL and the 250 mL

shake-flask controls (Figure 3). This was further supported by

the resulting maintenance coefficients for the bioreactors.

Recall that the maintenance coefficient of a root culture is the

portion of the total-sugar substrate it requires to maintain its

accumulated biomass. The maintenance coefficients of the LDT and

the GDT treatments of 1.09 and 1.49 g sugar g-1 DW,

respectively, were significantly greater than that of the normal

EFBR treatment of 0.30 g sugar g-1 DW and

statistically indistinguishable from that of the SSBR of 0.70 g

sugar g-1 DW, indicating that the roots in the LDT

and GDT treatments were expending via respiration a great

portion of their sugar substrates in maintaining their

accumulated biomass. The results demonstrate that the roots in

the LDT and GDT treatments were physiologically stressed, though

the cause of stress was clearly not sugar mass-transfer

limitations. Further, measurements of oxygen consumption rates

showed that the LDT treatment and the GDT treatment on day 18

also had an average value of 0.05 mg min-1 g-1

DW, which was statistically the same as that for the EFBR and

the SSBR.

Thus, the roots’ relative ability to consume oxygen could not

have accounted for the poor growth performance of the LDT and

the GDT treatments. All the bioreactors, however, were observed

to exhibit extensive bubble entrapment, coalescing and

channeling during their respective liquid phases, pointing to

the presence of external boundary layers as well as localized

stagnant regions within the bioreactors during the liquid dwell

time. Thus, without the benefit of more frequent or sufficient

forced convective flow generated by the ebb-and-flow action,

bioreactors with an extended or permanent liquid phase, like the

LDT treatment and the SSBR control, suffered from oxygen

mass-transfer limitations. The GDT treatment, also lacking a

sufficient forced convective flow to overcome the mass-transfer

resistances created by its stagnant root-entrained medium during

its prolonged gas phase, must have also experienced oxygen

mass-transfer limitation during the prolonged GDT. It was

noteworthy that the normal EFBR, the LDT treatment and the GDT

treatment all had the same root-entrained medium of 0.5 mL g-1

DW. Thus, even though the frequencies of forced convective flow

of 22.2% and 16.7% in the LDT and GDT treatments, respectively,

were sufficient to obviate overall sugar mass-transfer

limitations, such frequencies proved not enough to prevent

oxygen mass-transfer limitations in these treatments. Thus,

during the prolonged liquid phase of the EFBR, oxygen

mass-transfer limitation began to prevail, conforming to normal

expectation. During the prolonged gas phase of the EFBR,

however, oxygen mass-transfer limitation also began to prevail,

if counter-intuitively.

Implications for Scale Up

The study by Cuello et al., (2003b) reinforced that the forced

convective delivery of oxygen is the most critical variable for

the successful scale up of the EFBR and, indeed, of any hairy

root bioreactor. This finding agrees squarely with those from

previous studies on the critical necessity of liquid convective

flow on the effective delivery of dissolved oxygen to roots

grown in liquid medium (Prince et al., 1991; Yu and Doran 1994;

Singh and Curtis 1994; Shiao and Doran 2000; Ramkrishnan and

Curtis 2004). The study by Cuello et al., (2003b) also

underscored, however, the oxygen-delivery limitations that exist

in gas-phase bioreactors (also known as liquid-dispersed

bioreactors, including the nutrient mist, spray and trickle-bed

bioreactors) on account of the existence of stagnant external

boundary layers in these bioreactors in addition to the

potential occurrence of liquid channeling and water-logging

(Shiao and Doran 2000; Williams and Doran 2000; Ramkrishnan and

Curtis 2004). Quite simply, there is no convincing proof that

oxygen mass transfer limitation does not exist in these

gas-phase bioreactors. Weathers et al., (1999), for instance,

concluded from their study of 1.5 L nutrient-mist and

bubble-column bioreactors, based on mRNA levels of the

fermentation enzyme alcohol dehydrogenase (ADH), that the bubble

column was oxygen-limited since it exhibited expression of ADH,

while the mist bioreactor was not oxygen-limited since it did

not exhibit expression of ADH. (The bubble column yielded 1.7

times more dry biomass than the mist bioreactor.) Unfortunately,

however, the measurement of the activity of fermentation enzymes

such as ADH as an indicator of hypoxia in hairy root bioreactors

has proved unreliable, since cases have been reported where

oxygen-limited treatments and the non-oxygen-limited control

showed exactly the same levels of ADH activity, or the

oxygen-limited treatments failed to show elevated levels of ADH

activity (Shiao et al., 2002). Further, the treatments that

showed elevated levels of ADH activity ended up yielding greater

biomass growth, and the treatments that showed little or no ADH

activity ended up yielding lower biomass growth (Weathers et

al., 1999; Kim et al., 2002; Shiao et al., 2002). Thus, a

successful detection of ADH activity is neither a necessary nor

a sufficient indicator of the presence of oxygen limitation.

Conversely, failure to detect ADH activity is neither a

necessary nor a sufficient indicator of the absence of oxygen

limitation.

What is clear, however, is that there is a need both in

liquid-phase and in gas-phase bioreactors for a

forced-convective action to be employed in proper frequency to

overcome the mass-transfer resistances offered by the stagnant

external boundary layers and/or dead zones which normally exist

in the high-density hairy-root bioreactor environment. One way

to generate such forced-convective action is by employing the

ebb-and-flow regime, making the ebb-and-flow regime an effective

strategy for overcoming the scale-up challenges of hairy-root

production in bioreactors.

It is noteworthy that in compiling the results of 22 different

studies that presented 26 different hairy-root bioreactor

treatments (representing various combinations of different

bioreactor sizes, growth periods, and bioreactor types –

including stirred tank, bubble column, isolated impeller,

convective flow, nutrient mist, trickle/spray),

Ramakrish-nan and Curtis (2004) found that the bioreactor that

yielded the highest average specific growth rate -- for a

bioreactor that was at least 2 L in size, had a growth period of

at least 18 days, and had a dry biomass output of at least 10 g

L-1 was the ebb-and-flow bioreactor by Cuello (1994)

(Figure 5), which gave an average specific growth rate of 0.22 d-1.

It was telling that the one that came the closest to the EFBR

was a trickle-bed bioreactor by Ramakrishnan and Curtis (2004),

which gave an average specific growth rate of 0.21 d-1,

but one which was operated under an enriched-oxygen condition.

Figure 5.

A 2.5-L ebb-and-flow bioreactor (EFBR) during gas dwell time and

growing 18-day-old hairy roots.

It is worth pointing out that the performance of the normal EFBR

in the study by Cuello (1994) and Cuello et al., (2003b) had yet

to be optimized. With its FT and DT set constant at 1 min each

throughout the entire growth period while the hairy roots were

growing, the pump flow rate had to be continually reduced over

time so that it would deliver just enough liquid medium into the

bioreactor vessel to reach a constant level during each FT of 1

min. With more root biomass accumulating and occupying more

space inside the vessel over time, less and less liquid had to

be pumped into the vessel during FT. This meant that the flow

velocity of the nutrient medium through the root biomass in the

normal EFBR treatment kept being reduced just as the

mass-transfer resistance offered by the roots was increasing.

Clearly, there was room for further improvement of the

performance of the normal EFBR treatment.

Incidentally, the results by Cuello et al., (2003b) made clear

why the only previous attempt made by Taya et al., (1989) to

employ an ebb-and-flow bioreactor to grow immobilized hairy

roots (Armoracia rusticana) simply failed. Since their

300 mL EFBR used a liquid-phase duration of 15 minutes (i.e.,

much greater than the 4 min [FT + LDT + DT] used in the

foregoing study) plus a GDT of 8 h it could be safely inferred

that their system suffered from significant oxygen mass-transfer

limitations.

The EFBR can demonstrably meet all of the four minimum

requirements of a hairy root bioreactor for scale up. To wit:

(1) its characteristic configuration (e.g., flow configuration,

geometric configuration, etc.) remains operative, and does not

degrade, upon scale up; (2) it can make the nutrients and oxygen

available, or accessible, to the roots throughout the reaction

volume by proper adjustment of its LDT, GDT, FT and DT; (3) it

can supply both nutrients and oxygen to the roots in sufficient

concentrations throughout the reaction volume by proper

adjustment of its LDT, GDT, FT and DT; and (4) it lends itself

to the scale up process by possessing identifiable and

quantifiable characteristic process parameters which can be

duplicated at larger scales with relative ease and economy.

Examples of potential scale-up process parameters for the EFBR

include dissolved oxygen concentration at a specified location

in the bioreactor, volumetric flow rate, volumetric flow rate

per unit volume, Reynold’s number, power, and power per unit

volume, among others.

Finally, in scaling up the EFBR, there exists a maximum

allowable height for the EFBR column since the dissolved oxygen

in the liquid medium will be continuously consumed by the roots

as the liquid medium passes through the root bed along the

length of the EFBR column. It should be noted that the same is

true in the case of the continuous convective flow bioreactor

(CFR). Cuello (1994) recommended that, in industrial

applications, the most efficient and economical way of operating

the EFBR would be for two equal-sized EFBR’s to be operated in

tandem so that when one is drained, its medium is transferred to

fill the other. This mode of operation would obviate the need

for a costly sterile media reservoir which naturally would have

the same volume as that of the EFBR. Further, it was recommended

that LDT = GDT = 0 in order to maximize the allowable durations

for the FT and the DT. Indeed, their calculations showed,

adopting a value for the maximum tolerable flow velocity for the

roots of 16 cm s-1, that the allowable maximum height

for their specific EFBR design was 23 m (or 75 ft).This

corresponded to FT = DT = 3 min, specifying that that dissolved

oxygen was at saturation level in the liquid when introduced

into the EFBR at the beginning of FT and allowed to drop to no

less than 40% of saturation when the liquid exited the EFBR at

the end of the DT.

ELECTRICAL ELICITATION

Elicitation is the process whereby a molecule or a stress agent

induces a plant organ, tissue or cell to synthesize and

accumulate phytoalexins. Phytoalexins are antimicrobial chemical

compounds or secondary metabolites which in nature are

synthesized and accumulated by plants after exposure to

microorganisms (Darvill and Albershein 1984). Biotic elicitors

are molecules which are either pathogen-derived (so-called

exogenous elicitors, that is, with respect to the plant) or

plant-derived (so-called endogenous elicitors, also with respect

to the plant). Meanwhile, abiotic elicitors are physical or

chemical agents that induce physiological stress to plants,

leading to the synthesis and accumulation of phytoalexins.

Examples of abiotic elicitors include UV radiation, ethylene,

antibiotics, fingicides, salts of heavy metals, heat and cold,

etc.

The first biotic elicitor to be studied extensively, the peptide

monilicolin A, was obtained from the mycelia of the fruit-tree

fungal pathogen Monilinia fructicola (Darvill and

Albershein 1984). Oligosaccharides, polysaccaharides,

glycoproteins and organic acids derived from the mycelia and/or

cell walls of fungal microorganisms are some of the classes of

exogenous elicitors that have been reported, while

galacturonosyl residues have been reported to constitute a class

of endogenous elicitors (Darvill and Albershein 1984).

Examples of biotic elicitors that have been applied to hairy

root cultures to elicit the production of secondary metabolites

include those derived from Aspergillus niger for

Tagetes patula hairy roots (Buitelaar et al., 1993), those

derived from Rhizoctonia solani for H. muticus

hairy roots (Singh et al., 1994), and those derived from

Botrytis spec., Pythium aphanidermatum,

Rhodotorula rubra, Alternaria zinnae,

Colletotrichum gloeosporoides, Helminthosporium gramineum,

Sclerotinia sclerotiorum and Verticillium dahliae

for Papaver somniferum hairy roots (Eilert et al., 1985).

Meanwhile, examples of abiotic elecitors that have been applied

to hairy root cultures to elicit the production of secondary

metabolites include osmotic shock on H. muticus hairy

roots (Halperin and Flores 1997), and salicylate and methyl

jasmonate on Tanacetum parthenium hairy roots

(Stajokowska et al., 2002).

The mode of action of abiotic elicitors on plants has been

postulated in various ways, including through the release of an

endogenous elicitor compound from the plant cell (Moesta and

Grisebach 1981), through inhibition of the degradative turnover

of secondary metabolites (Yoshikawa 1978), and through the

involvement of a second messenger molecule that transmits

signals from the plasma membrane to trigger the transcription

and translation of enzymes (DiCosmo and Misawa 1985).

Electricity as an Elicitor

Elicitation has long been proposed as a potential strategy for

increasing the production of secondary metabolites by plant cell

or root cultures in vitro while they are being grown in

bioreactors (Dornenburg and Knorr 1995). There are significant

challenges, however, in employing elicitors, including: (1) the

labor required to prepare biotic elicitors from their biological

sources; (2) loss of capacity of biotic elicitors over time to

elicit the biosynthesis of desired secondary metabolites; (3)

potential adverse or toxic effects of biotic or abiotic

elicitors on the cell or root culture; and (4) difficulty of

separating or removing biotic or abiotic elicitors from the

culture once they have been added. While with respect to the

last point, UV light (an abiotic elicitor) provides the

convenience of lending itself to simply being turned on or off

as needed, the poor penetration of light through thick clumps of

hairy roots in a large-scale bioreactor constitutes a

significant challenge to subjecting all the roots in the

bioreactor uniformly to the elicitation process, especially when

the UV light is applied externally to the bioreactor. Inserting

UV lamps into the bioreactor interior, however, would waste

bioreactor space or volume, would add complexity to bioreactor

maintenance, cleaning, and sterile operation, and could

significantly interfere with the bioreactor’s hydrodynamic or

aerodynamic characteristics.

The use of electricity, however, as an abiotic elicitor obviates

the foregoing challenges. Similar to UV light, electricity

provides the convenience of lending itself to simply being

turned on or off as needed. Further, electricity would be

conducted much more efficiently than light through the thick

clumps of hairy roots in a large-scale bioreactor when the hairy

roots are immersed in their normal nutrient solution containing

electricity-conducting ions, allowing for all the roots in the

bioreactor to be subjected to the elicitation process in a

convenient manner. Also, implementing electrical elicitation

would only require two thin metal electrodes to be inserted

through the roots inside the bioreactor along the height of the

root bed. Alternatively, the electrodes or even metal plates

could be positioned against opposite inside walls of the

bioreactor if interference with the flow characteristics of the

bioreactor would be a concern.

The application of electricity in plant systems has been

traditionally focused on the effects of the presence of electric

fields or pulses on the following: (1) enhancement of the

proliferation rate of plant biomass (Rathore and Goldsworthy

1985); (2) increase in the rate and efficiency of plant

regeneration (Rathore and Goldsworthy 1985); (3) improvement of

the rate and success of seed germi-nation (Kazanova 1972); (4)

stimulation of protoplast division Rech et al., 1987); and (5)

enhancement of DNA synthesis in cultured plant protoplasts (Rech

et al., 1988). Takeda et al., (1988) correlated the membrane

potential of cultured carrot cells with their synthesis of

anthocyanin. They varied the membrane potential of the carrot

cells, however, by manipulating the concentration of K+

ions and by adding various levels of 2,4-D into the culture

medium, and not by subjecting the cells to an electric field.

Working with alternating current (AC) and direct current (DC)

and how they affect the production of secondary metabolites of

H. muticus hairy roots, Cuello and Yue (1998) and Johnson

and Cuello (1998) appear to be the first to investigate the

electrical elicitation of secondary metabolites from hairy root

cultures. Both studies employed a 6.3 cm x 6.3 cm x 5.1 cm

plexi-glass electrical elicitation box or chamber equipped with

two stainless-steel metal plates, serving as electrodes,

positioned against opposite inside walls of the box (Figure 6).

The hairy roots were placed inside the box and were immersed in

their normal nutrient solution before carrying out the

electro-elicitation process.

Figure 6.

Schematic of an electrical elicitation box equipped with

stainless-steel metal plates, serving as electrodes, placed

against opposite inside walls of the box.

A decidedly more comprehensive study on electrical elicitation

was recently conducted by Kaimoyo et al., (2008), using hairy

roots of pea (Pisum sativum, L, var. Little

Marvel) as the primary model system. Kaimoyo et al., (2008) used

the same elicitation box that Cuello and Yue (1998) and Johnson

and Cuello (1998) had used earlier. Trying different levels of

root biomass and electric current, their results showed that 2 g

of hairy roots exposed to 100 mA current for 1 h or 10 g of

hairy roots exposed to 30 or 50 mA current for 1 h produced very

similar levels of the secondary metabolite pisatin, which

averaged 32.1

±

3.9

mg g-1 FW.

This amount of pisatin was comparable to that obtained using

0.08 mM aqueous CuCl2 as an abiotic elicitor of de

novo pisatin biosynthesis (37

±

3.3 g g-1 FW). They also found that, though the

average length of the electro-elicited hairy roots six days

after treatment was slightly less than that for the control, the

rate of growth from six days on was the same as that of the

non-elicited hairy roots. And when these hairy roots were

re-elicited with 0.08 mM CuCl2 or a 30 mA current,

they produced similar amounts of secondary metabolites as

produced by hairy roots that had not been elicited previously.

Their gross morphology also did not differ from that of

non-elicited controls.

More interestingly, Kaimoyo et al., (2008) tested electrical

elicitation on other plant species known to synthesize

phytoalexins and other secondary metabolites upon elicitation by

various biotic and abiotic elicitors. Cell suspension cultures

of Arabidopsis (Arabidopsis thaliana L.) and

barrel medic (Medicago truncatula L.), roots of

chickpea (Cicer arietinum L.) and fenugreek (Trigonella

foenum-graecum L.), intact seedlings of sorghum (Sorghum

bicolor L.), Japanese pagoda tree (Sophora japonica

L.) and red clover (Trifolium pratense L.) were

electro-elicited at 30 mA current for 1 h. Secondary metabolites

were extracted 24 h later and compared by HPLC or HPLC coupled

to mass–spectrometry (HPLC-MS) with those extracted from

non-elicited tissues. Except for Arabidopsis and

sorghum, there were substantial increases in most of the

compounds whose biosynthesis had been shown previously to be

stimulated by elicitors. The resulting ratios of compound

produced with elicitation to compound produced by the

non-elicited control were: 2.8 for medicarpin as produced by

fenugreek roots; 4.3 for formononetin as produced by chickpea

roots; 44.0 for maackiain, 5.0 for medicarpin and 15.6 for

formononetin as produced by red clover seedlings; 34.5 for

afrormorsin, 168.1 for medicarpin, 7.0 for irisolidone, 7.6 for

formononetin, 3.6 for naringenin, 3.8 for hispidol, 3.5 for

tricin and 5.2 for isoflav-3-ene as produced by barrel medic

cells in suspension.

The authors noted that, in addition to the expected compounds,

the HPLC profiles of the extracts from many of the plants showed

the presence of other previously undetected secondary

metabolites. For instance, extracts of chickpea roots showed a

large increase in formononetin, maackiain and medicarpin as well

as over 20 other metabolites. The production of secondary

metabolites by cell suspension cultures of barrel medic showed

an even greater increase in the number of compounds as 55

compounds showed at least a 2-fold increase in the

electro-elicited tissue compared to the non-electro-elicited

controls. In the cell suspension cultures of Arabidopsis the

expected accumulation of camalexin was not observed. Silver

nitrate, previously reported to induce camalexin biosynthesis in

leaf tissue, was used as a positive control, but no camalexin

was obtained from silver nitrate-treated Arabidopsis cell

suspensions. However, two peaks with residence time or RT = 9

min and 13 min, respectively were observed in the HPLC

chromatogram of extracts from electro-elicited Arabidopsis

cell suspension cultures that were absent in non-elicited

cell suspensions. In sorghum seedlings, several different

metabolites were detected in the extracts of both elicited and

non-elicited tissue, but the differences in the amounts of these

compounds were not significant.

The study by Kaimoyo et al., (2008) clearly indicated that

electric current constitutes a general abiotic elicitor of plant

secondary metabolites. As with other abiotic elicitors, the

mechanism of action of electricity as elicitor on plants could

potentially involve the release of an endogenous elicitor

compound from the plant cell (Moesta and Grisebach 1981), the

inhibition of the degradative turnover of secondary metabolites

(Yoshikawa 1978), and/or the involvement of a second messenger

molecule that transmits signals from the plasma membrane to

trigger the transcription and translation of enzymes (DiCosmo

and Misawa 1985).

Electrical Elicitation of

Hyoscyamus muticus Hairy Roots

In our own study, 14-day-old H. muticus hairy roots were

subjected for 1 h to 12 mA, 67 mA and 158 mA of direct current

(DC) and to 11 mA, 28 mA, and 288 mA of 60-Hz alternating

current (AC). Weighing an average of 16.3 g per treatment, the

roots were treated for alkaloid extraction by the method of

Kamada et al., (1986), and alkaloid extracts dissolved in

methanol were assayed using HPLC (Shimadzu) equipped with

SIL-10A autoinjector and SPD-M10A photodiode array detector.

Samples were injected at a volume of 20 mL and were separated

isocratically in a Nova-Pak C18 (Waters) steel column (3.9 x 150

mm) using a mobile phase of 12.5% (v v-1)

acetonitrile and 87.5% (v/v) aqueous phosphoric acid (0.3% v/v),

adjusted to pH 2.2 with triethylamine, at a flow rate of 0.8 mL

min-1.

While the average pH of the roots’ B5 liquid medium did not

significantly change after elicitation, the medium’s average

electrical conductivity increased significantly for all

treatments after elicitation. For the DC treatments, the average

electrical conductivity rose from 1.8 to 10.0 mS cm-1

for 12 mA, 0.9 to 8.8 mS cm-1 for 67 mA, and 0.8 to

19.3 for 158 mA. For the AC treatments, the average electrical

conductivity rose from 1.5 to 7.8 mS cm-1 for 11 mA,

1.6 to 6.6 mS cm-1 for 28 mA, and 0.9 to 27.8 for 288

mA.

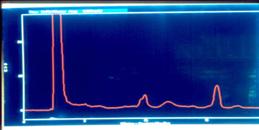

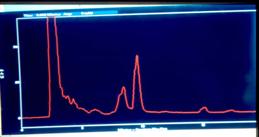

The resulting HPLC chromatograms at 215 nm of the roots’

alkaloid extracts showed pronounced differences between those

for the elicited treatments and those for the unelicited control

(Figure 7). Compound I (RT = 8.6 min) was significantly elicited

or overproduced when the roots were electro-elicited using

either AC or DC elicitation (Table 2). Indeed, the ratios of the

level of Compound I in an elicited treatment to that in the

control ranged from 11.0 to 13.5 for the AC treatments, while

those for the DC treatments ranged from 3.8 to 14.4. By

contrast, however, the levels of Compound II (RT = 9.8 min)

remained statistically indistinguishable between the elicited AC

or DC treatments and the unelicited control (Table 2). And,

interestingly, the synthesis of Compound III (RT = 16.0) was

significantly inhibited by both AC and DC electrical

elicitation.

Thus, the results of this study showed that in the case of H.

muticus hairy roots, electrical elicitation significantly

overproduced compound I, significantly inhibited compound III,

and had no appreciable effect on the level of compound II. It is

likely that the employment of electrical elicitation to a

specific plant species will have these three general effects on

the plant’s specific sets of secondary metabolites.

EBB-AND-FLOW BIOREACTOR

REGIME AND ELECTRICAL ELICITATION

Based on the foregoing sections, the ebb-and-flow regime and

electrical elicitation constitute two novel and promising

effective strategies for realizing the large-scale production of

secondary metabolites from hairy roots growing in scaled-up

bioreactors. Employing the ebb-and-flow regime would provide the

forced-convective action that is needed to overcome the

mass-transfer resistances offered by the stagnant external

boundary layers and/or dead zones which normally exist in the

high-density hairy-root bioreactor environment – both in

liquid-phase and in gas-phase bioreactors. Meanwhile, employing

electrical elicitation could significantly overproduce valuable

secondary metabolites produced by the hairy roots. Combining the

two strategies could certainly help achieve the economic

feasibility of the large-scale production from plant hairy roots

of specific secondary metabolites.

Figure 7.

Replicate HPLC chromatograms at 215 nm of the alkaloid extracts

from Hyoscyamus muticus hairy roots for the control

(upper) and for an electro-elicited treatment [12 mA DC] (low).

The x-axis is retention time (RT) and the y-axis is absorbance

units. Compound I has RT = 8.6 min, Compound II has RT = 9.8

min, and Compound III has RT = 16.0 min.

Table 2.

Average levels of compound I (RT = 8.6 min) and compound II (RT

= 9.8 min) based on the HPLC chromatograms at 215 nm of the

alkaloid extracts from Hyoscyamus muticus hairy roots.

The letters “a”, “b” and “c” denote statistical differences

between the control and the AC and DC electro-elicitation

treatments.

|

|

Compound I |

Compound II |

|

Average peak Area

(1000x) |

Elicited/Control |

Average peak Area

(1000x) |

Elicited/Control |

|

Unelicited control |

31.3a |

1.0 |

292.0a |

1.0 |

|

Elicited AC treatments |

|

|

|

|

|

11 mA |

423.4b |

13.5 |

298.4a |

≈ 1.0 |

|

28 mA |

366.8b |

11.7 |

345.1a |

≈ 1.0 |

|

288 mA |

346.5b |

11.0 |

325.5a |

≈ 1.0 |

|

Elicited DC treatments |

|

|

|

|

|

12 mA |

420.8b |

13.4 |

514.7a |

≈ 1.0 |

|

67 mA |

453.5b |

14.4 |

342.8a |

≈ 1.0 |

|

158 mA |

120.0c |

3.8 |

359.1a |

≈ 1.0 |

REFERENCES CITED

Buitelaar RM,

Leenan EJTM, Geurtsen G, de Groot AE, Tramper J (1993).

Effects of the addition of XAD-7 and of elicitor treatment on

growth, thiopene production, and excretion by hairy roots of

Tagetes patula. Enzyme Microb Technol 15: 670-676

Cuello JL,

Walker PN, Curtis WR

(2003a). Design of ebb-and-flow biorector (EFBR) for immobilized

hairy root cultures, Part I: Preliminary design models and culture

parameters. Trans ASAE 46: 1457-1468

Cuello JL,

Walker PN, Curtis WR

(2003b). Design of ebb-and-flow biorector (EFBR) for immobilized

hairy root cultures, Part II: Growth studies and model

verifications. Trans ASAE 46: 1469-1476

Cuello JL, Yue LC

(1998). Electrical elicitation of secondary metabolites from in

vitro root cultures. The University of Arizona Office of the

Vice President for Research Small Grant Program Report. The

University of Arizona, Tucson, AZ

Cuello JL

(1994). Design and scale up of ebb-and-flow bioreactor (EFBR) for

hairy root cultures. PhD dissertation, University Park, Penn State

University, State College, PA

Cuello JL, Walker PN,

Curtis WR

(1991). Ebb-and-flow bioreactor for hairy root cultures. ASAE Paper

No. 91-7528. St. Joseph, Mich: ASAE

Darville AG, Albershein P

(1984). Phytoalexins and their elicitors – a defense against

microbial infection in plants. Ann Rev Plant Physiol 35:

243-275

Dawson RF

(1942). Nicotine synthesis in excised tobacco roots. Amer J Bot

29: 813-815

DiIorio AA, Cheetham RD, Weathers PJ (1992). Growth of transformed roots

in a nutrient mist biorector: Reactor performance and evaluation.

App Microbiol Biotechnol 37: 457-462

Dornenburg H, Knorr D

(1995). Strategies for the improvement of secondary metabolite

production in plant cell cultures. Enzyme Microb Technol 17:

674-684

Eilert U, Kurz WGW, Constabel F

(1985). Stimulation of sanguinarine accumulation in Papaver

somniferum cell cultures by fungal elicitors. J Plant Physiol

119: 65-76

Flores HE, Dai YR, Cuello JL,

Maldonado-Mendoza IE, Loyola-Vargas VM

(1993). Green roots: Photo-synthesis and photoautotrophy in an

underground plant organ. Plant Physiol 101: 363-37

Flores HE, Curtis WR

(1991). Approaches to understanding and manipulating the

biosynthetic potential of plant roots. Proc NY Acad Sci 655:

188-209

Flores HE

(1987). Use of plant cells and organ culture in the production of

biological chemicals. In Biotechnology in Agricultural Chemistry,

Washington, DC: ACS Symposium Series

Halperin SJ, Flores HE

(1997). Hyoscyamine and praline accumulation in water-stressed

Hyoscyamus muticus hairy root cultures. In Vitro Cell Dev Biol

Plant 33: 240-244

Hamill JD, Parr AJ, Rhodes M, Robins RJ, Walton NJ (1987). New routes to

plant secondary products. Bio Technology 5: 800-804

Hilton MG, Rhodes

MJC

(1990). Growth and hyoscyamine production of hairy root cultures

of Datura stramonium in a modified stirred tank reactor.

Applied Microbiol Biotechnol 33: 132-138

Johnson M, Cuello JL

(1998). Overproduction of plant-produced chemicals from in vitro

root cultures. 1997-1998 The Spirit of Inquiry. Abstract,

Undergraduate Research, The University of Arizona Honors Center.

Tucson, AZ

Kaimoyo E, Farag MA,

Sumner LW, Wasmann C, Cuello JL, Van Etten H (2008).

Sub-lethal levels of electric current elicit the biosynthesis of

plant secondary metabolites. Biotechnol Prog 24: 377 -384

Kamada H, Okamura N,

Satake M, Harada H, Shimomura K

(1986). Alkaloid production by hairy root cultures in Atropa

belladonna. Plant Cell Reports 5: 239-242

Kanokwaree K, Doran PM

(1998). Application of membrane tubing aeration and

perfluorocarbon to improve oxygen delivery to hairy root cultures.

Biotechnol Prog 14: 479-486

Kanokwaree K, Doran PM

(1997). The extent to which external oxygen transfer limits growth

in shake flask culture of hairy roots. Biotechnol Bioeng 55:

520-526

Kazanova ZM

(1972). After-sowing processing of spring wheat seeds in electrical

constant current. Electr Process Mat. 4: 71-72

Kim YJ, Weathers PJ,

Wyslouzil B

(2002). Growth of Artemisia annua hairy roots in liquid and

gas-phase reactors. Biotechnol Bioeng 80: 454-464

Kondo O, Honda H,

Taya M, Kobayashi T

(1989). Comparison of growth properties of carrot hairy root in

various bioreactors. Applied Microbiol Biotechnol 32: 291-294

Kwok KH, Doran PM

(1995). Kinetic and stoichiometric analysis of hairy roots in

segmented bubble column reactor. Biotechnol Prog 11: 429-435

Medina-Bolivar F, Condori

J, Rimando AM, Hubstenberger J, Shelton K, O’Keefe SF, Bennett S,

Dolan MC

(2007). Production and secretion of resveratrol in hairy root

cultures of peanut. Phytochem 68: 1992-2003

Medina-Bolívar F, Cramer C

(2004). Production of recombinant proteins by hairy roots cultured

in plastic sleeve bioreactors. In Methods in Molecular Biology:

Recombinant Gene Expression. 2nd ed.

Paulina Balbás and Argelia Lorence

(eds). Molecular Biology Series. Humana Press, Totowa, 535 pp

Medina-Bolivar F, Wright

R, Funk V, Sentz D, Barroso L, Wilkins TD, Petri W, Cramer CL (2003). A non-toxic

lectin for antigen delivery of plant-based mucosal vaccines. Vaccine

21: 997-1005

Ramakrishnan D, Curtis WR

(2004). Trickle-bed root culture bioreactor design and scale up:

growth, fluid dynamics and oxygen mass transfer. Biotechnol Bioeng

88: 248-260

Ramakrishnan D, Curtis WR

(1995). Elevated meristematic respiration in plant root cultures:

implications to reactor design. J Chem Eng Jpn 28: 491-493

Rathore KS, Goldsworthy A

(1985). The electrical control of growth in plant tissue cultures:

the polar transport of auxin. J Exp Bot 36: 1134-1141

Rech EL, Ochatt SJ, Chand

PK, Davey MR, Mulligan BJ, Power JB

(1988). Electroporation increases DNA synthesis in cultured plant

protoplasts. BioTechnology 6: 1091-1093

Rech EL, Ochatt SJ, Chand

PK, Power JB, Davey MR

(1987). Electroenhancment of division of plant-protoplast-derived

cells. Protoplasma 141: 169-176

Rhodes MCJ, Hilton M, Parr

AJ, Hamill JD, Robins RJ

(1986). Nicotine production by hairy root cultures of Nicotiana

rustica: Fermentation and product recovery. Biotechnol Letters

8: 415-420

Shiao T, Doran PM

(2000). Root hairiness: Effect on fluid flow and oxygen transfer in

hairy root cultures. J Biotechnol 83: 199-210

Shiao T, Ellis MH, Dolferus R, Dennis ES, Doran PM

(2002). Overexpression of alcohol dehydrogenase or pyruvate

decarboxylase improves growth of hairy roots at reduced oxygen

concentrations. Biotechnol Bioeng 77: 455-461

Singh G, Reddy GR, Curtis

WR

(1994). Use of binding measurements to predict elicitor dosage

requirements for secondary metabolite production from root cultures.

Biotechnol Prog 10: 365-371

Stojakowska AJM, Kisiel W

(2002). Salicylate and methyl jasmonate differentially influence

diacetylene accumulation pattern in transformed roots of feverfew.

Plant Sci 163: 1147-1152

Takeda J, Senda M, Ozeki

Y, Komamine A

(1988). Membrane potential of cultured carrot cells in relation to

the synthesis of anthocyanin and embryogenesis. Plant Cell Physiol

29: 817-824

Taya M, Yoyama A, Kondo O,

Kobayashi T

(1989). Growth characteristics of plant hairy roots and their

cultures in bioreactors. J Chem Engin Jpn 22: 84-89

Weathers PJ,

Wyslouzii BE, Wobbe KK, Kim YJ, Yigit E

(1999). Workshop on Bioreactor Technology: The biological response

of hairy roots to O2 levels in bioreactors. In Vitro Cell

Develop Biol Plant 35: 286-289

Williams RC, Doran

PM

(2000). Hairy root culture in a liquid-dispersed bioreactor:

Characterization of spatial heterogeneity Biotechnol Prog 16:

391-401

Yu S, Doran PM

(1994). Oxygen requirements and mass transfer in hairy-root

culture. Biotechnol Bioeng 44: 880-887

Accepted for

publication: 18 October 2008

|