Mist reactors: principles, comparison of various

systems, and case studies

Pamela

Weathers1,2, Chunzhao Liu1,3,

Melissa Towler2, and Barbara Wyslouzil4

1

Arkansas State University, Jonesboro, AR; 2 Worcester

Polytechnic Institute, Worcester, MA;

3

National Key Laboratory of Biochemical Engineering, Beijing,

China; 4 The Ohio State University, Columbus, OH

*Corresponding author; email:

weathers@wpi.edu

Keywords:

Artemisia annua, scale-up, gas-phase reactors

ABSTRACT

Growing

hairy roots in bioreactors has proven challenging. Here we

summarize the recent work using a novel bioreactor, the mist

reactor, for the culture of hairy roots from many plant species.

Compared to most liquid-phase bioreactors, this gas-phase

bioreactor offers a completely different environment for growing

roots. Design, modeling, and some of the unique engineering

aspects inherent to mist reactors are explained along with some

of the biological responses of roots when grown in mists

compared to liquids. Prospects for future development of this

technology are also summarized.

INTRODUCTION

Hairy roots

can produce novel compounds not found in the whole plant or in

untransformed roots (Flores and Medina-Bolivar, 1995; Wysokinska

and Chmiel, 1997; Flores et al., 1998), often at levels

exceeding those found in the parent plant (Wysokinska and

Chmiel, 1997; Wysokinska and Rozga, 1998; Rao and Ravishankar,

2002). They also offer significant advantages for the production

of engineered proteins (Guillon et al., 2006; Zhang et al.,

2005; Shanks and Morgan, 1999). Although there are some reports

of co-cultured differentiated tissues (e.g. shoots plus roots)

being used to produce secondary metabolites (Mahagamasekera and

Doran, 1998; Subroto et al., 1996), most efforts are focused on

hairy roots.

Several

bottlenecks, however, hamper the routine production of

compounds, especially secondary metabolites, from hairy roots.

The two main challenges are: (1) for many products the

biochemical pathways and their regulation are not understood;

and (2) although progress has been made, cost effective

scaleable production systems are not yet well developed.

Developing an inexpensive scaleable reactor for hairy roots

would address the latter problem, enabling large-scale culture

and the production of many important and valuable chemicals

(Guillon et al., 2006). Recent political challenges to the

release of transgenic plants further warrant the use of

controlled production schemes including the use of low cost

bioreactors (Guillon et al., 2006).

Our

research has focused on gas-phase (mist) reactors, because this

environment reduces the gas-exchange limitations and the high

shear conditions normally found in liquid-phase reactors. Unlike

growth in liquid systems, roots grown in mist reactors are not

oxygen limited (Weathers et al., 1999) even at high bed

densities (Kim, 2001), and the production of secondary

metabolites is often greater in mist reactors than in liquid

phase reactors (Kim et al., 2001; Bais et al., 2002). High

biomass density is required for a reactor system to be

economically viable, and the maximum root tissue concentration

that can be achieved in a bioreactor depends on the efficient

mass transfer of oxygen and other nutrients into the dense root

matrix (Curtis, 2000). A point in favor of gas phase reactors is

that roots are more able to compensate for poor liquid

dispersion than for poor gas dispersion within a reactor

(McKelvey et al., 1993). A recent comparison by Suresh et al.

(2005), also verified that a mist bioreactor is superior to

other reactor designs for hairy root growth. Finally,

establishing a hairy root culture on solid medium does not

guarantee that they will grow well in liquid medium (Hallard et

al., 1997), so gas-phase reactors may be the only option.

Together these results provide compelling reasons to study mist

reactors.

Recent

reviews have added new perspectives regarding the prospects and

challenges of producing secondary metabolites from hairy roots

in bioreactors (Kim et al., 2002; Towler et al., 2006; Weathers

et al., 2006). These reactors, however, have not yet been scaled

to commercially useful sizes. The key scale-up concerns for

hairy root bioreactors include the following: the flow and

geometric configurations should be scale independent; high

growth rates must be maintained with no limitations in liquid

and gas (O2) nutrients; the key operating parameters

must be identifiable and measurable so that scale-up can be

achieved easily and economically (Cuello et al., 2003). Here we

provide a review on mist/spray reactors and the efforts to scale

them up.

LIQUID VS. GAS PHASE

REACTORS

O2,

CO2 and C2H4 are the three

gases most important to plants, but all are poorly soluble in

water; their solubility decreases with increasing nutrient

concentration and temperature (Atkinson and Mavituna, 1991;

Geankopolis, 1993), and oxygen is about 25 times less soluble

than CO2. To ensure rapid growth of roots, high

levels of oxygen are required while excessive CO2

accumulation must be prevented as the level of respiration

increases with increasing root biomass. Liquids therefore limit

the amount of gas available to growing roots.

Good gas

transfer into liquid media can be obtained by either dispersing

the liquid into the gas or by dispersing the gas into the

liquid. In liquid-based reactors, gas is dispersed into the

liquid phase, while in a mist reactor liquid is dispersed into

the gas phase. Liquid dispersion can be achieved using a number

of different methods including a spinning disk, a compressed gas

atomizer, or an ultrasonic droplet generator. The spinning disk

produces a wide range of droplet sizes and is mainly used in

whole plant aeroponic systems (Weathers and Zobel, 1992).

Smaller droplets have a larger surface to volume ratio that

facilitates gas transport into liquid. Compared to the spinning

disk, compressed gas atomizers can produce rather uniform

amounts of very small droplets thereby ensuring good gas

transfer into the liquid and thus, to the roots. Unfortunately

to obtain small droplets, the nozzle orifice must be small and,

as a result, it clogs easily.

Ultrasonically produced mists have proved to be the most

effective method of generating nutrient aerosols for in vitro

cultures and have, thus, been the focus of most mist reactor

studies with hairy roots. Earlier mist reactors used a submerged

ultrasonic transducer producing sound waves in the 1.7 MHz

range. Although the mechanism of energy transmission of this

type of misting system has been discussed in depth elsewhere

(Weathers and Wyslouzil, 2007), the transducer energy can affect

the mean droplet diameter, Dn, which depends on the

density ρ the surface tension of the liquid σ and the

transducer frequency Ʋ as Dn = 0.34(8πσ/ρ Ʋ2)(1/3)

(Lang, 1962). At higher frequencies Dn also depends

on the power density at the liquid surface (Tarr et al., 1991).

One of the

most important factors in a mist or spray reactor is the droplet

size, and Table 1 summarizes the three broad categories

generally used to classify droplets dispersed in a gas. Smaller

droplets have several advantages including long settling times

that ease transport and distribution of the dispersed nutrient

solution and enhance the ability of the small droplets to

penetrate dense tissue cultures and more evenly distributing

liquid nutrients, as well as large surface to volume ratios that

ensure good mass transfer of gases between the gas and liquid

phases enhancing gas transfer to the root tissue. If the droplet

size is too small, however, inadequate medium will be supplied

to the roots. Excessively large droplets, on the other hand,

will impede adequate gas transfer into the roots. Although the

optimum droplet size is not known, and has not been studied

other than by measuring droplet deposition in dense beds of

hairy roots (Wyslouzil et al., 1997), Weathers and Zobel (1992)

suggested that, for roots, the minimum acceptable droplet size

is probably about 1 mm.

Table 1.

Droplet size ranges for mists, fogs and sprays. (Perry and

Green, 1997; Weathers and Zobel, 1992; Whipple, 1995).

|

Droplet type |

Droplet diameter

(mm) |

Droplet forming system |

Droplet diameter

(mm) |

|

Mist |

0.01-10 |

ultrasonic systems |

1-35

Dv ~ 7-10 is typical |

|

Fog |

1-100 |

compressed gas atomizers |

1-100 |

|

Spray |

10-10,000 |

spray nozzles |

>100 |

A BASIC

MIST REACTOR

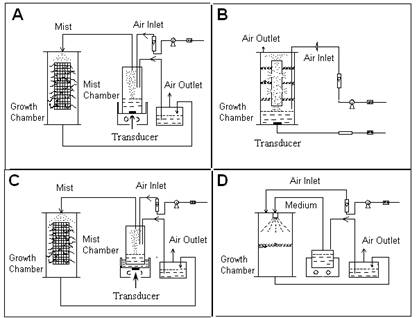

A basic

mist bioreactor (Figure 1) is rather simple. It is comprised of

a mist generating system, a culture medium reservoir, a liquid

pump (usually peristaltic), a sterile filtered air supply, a gas

flow meter, a timer to regulate misting time, and a culture

chamber. Most mist reactors also require a trellis or other

means of support for suspending roots in the growth chamber.

Figure. 1

Mist bioreactor designs for hairy root cultures: A) the

ultrasonic mist generator and growth chamber are in separate

vessels; the ultrasonic transducer (arrow) is inside the mist

generator sump; B) the ultrasonic mist generator and the growth

chamber are in the same vessel; C) the ultrasonic transducer

(arrow) is separated from the growth chamber sump by an acoustic

window which is also the base of the mist generator; D) trickle

bed bioreactor.

Table 2.

Summary of hairy root studies in mist or spray reactors.

|

Plant Genus |

Major Results |

System Used |

Working Vol. (L) |

Reference |

|

Artemisia

|

growth comparable to flasks and

plates |

acoustic window1 mist

reactor |

na |

Buer et al., 1996 |

|

modified inner-loop reactor growth

comparable to flasks |

submerged ultrasonics |

2.3 |

Liu et al., 1999 |

|

no O2 limitation, but 50%

less biomass than liquid systems |

acoustic window2 mist

reactor |

1.5 |

Weathers et al., 1999 |

|

altered branching rate versus flasks

– single root studies |

acoustic window2 mist

reactor |

na |

Wyslouzil et al., 2000 |

|

3x higher artemisinin content than

bubble column |

acoustic window2 mist

reactor |

1.5 |

Kim et al., 2001 |

|

growth comparable to bubble column |

acoustic window2 mist

reactor |

1.5 |

Kim et al., 2002a |

|

altered terpenoid gene expression

versus flasks |

acoustic window2 mist

reactor |

1.5 |

Souret et al., 2003 |

|

|

in 5% sucrose growth exceeded that in

shake flasks |

acoustic window2 small

mist reactor |

0.035 |

Towler et al., 2007 |

|

Beta |

growth comparable to flasks |

submerged ultrasonics |

1 |

Weathers et al., 1989 |

|

Carthamus |

growth comparable to flasks; 15%

faster than airlift reactor |

submerged ultrasonics |

1 |

DiIorio et al., 1992 |

|

Cichorium |

higher biomass and esculin content

than bubble column |

acoustic window3 mist

reactor |

1.75 |

Bais et al., 2002 |

|

Datura

|

1.6x lower doubling time than

submerged cultures |

droplet reactor |

2 |

Wilson et al., 1990 |

|

successful large-scale

culture |

hybrid submerged/ droplet reactor |

500 |

Wilson, 1997 |

|

Fragaria |

biomass yield higher than droplet

bioreactor |

mist reactor |

1 |

Nuutila et al., 1997 |

|

Hyoscyamus |

growth comparable to shake flask |

spray reactor |

0.30 |

McKelvey et al., 1993 |

|

Nicotiana |

50% lower doubling time than flasks |

spray reactor |

0.50 |

Whitney, 1990, 1992 |

|

Panax |

altered ginsenoside pattern versus

native rhizome |

spray reactor |

1 |

Palazon et al., 2003 |

|

Stizolobium

|

intermittent feeding promoted L-DOPA

production |

mist trickling reactor |

3 |

Huang et al., 2004 |

|

higher L-DOPA productivity with

higher inoculum density |

mist trickling reactor |

9 |

Huang and Chou, 2006 |

|

root branching increased biomass and

L-DOPA content |

mesh hindrance mist trickling reactor |

5 |

Sung and Huang, 2005 |

|

Tagetes |

growth and thiophene content

comparable to shake flask; higher than bubble

column, nutrient sprinkle |

acoustic window3 mist

reactor |

0.30 |

Suresh et al., 2005 |

1, Conap’s

EN6, 2, Teflon, 3, polycarbonate, na, not applicable.

It is

possible that the size of such a support structure can be

minimized if it is coated with poly-L-lysine to induce root

attachment (Towler et al., 2003). How these components are

designed and then configured has enabled a variety of mist

reactors to be employed for culturing many different biological

tissues or organisms. For example, mist reactors have been

successfully used to culture animal tissues (Friberg et al.,

1992), to study whole plants (Souret and Weathers, 2000;

Sharaf-Eldin and Weathers, 2006), in micropropagation (Correll

and Weathers, 2001a, 2001b; Correll et al., 2001; Weathers and

Giles, 1988 and 1989), and to culture hairy roots (Table 2).

Figure 1 illustrates some mist reactor designs that have been

employed for hairy root culture.

NUTRIENT

MIST DROPLET DEPOSITION MODEL

In

experiments by Kim et al. (2002), roots grown in a bubble column

reactor consistently yielded more dry mass than roots harvested

from a mist reactor. After comparing the biological demand of

the growing roots in the mist reactor to the level of substrate

(sugar) deposited on the roots as a function of reactor packing

fraction, and the deposition of medium droplets using a mist

deposition model (Wyslouzil et al., 1997), Kim et al. (2002)

suggested that roots at low packing fraction could not capture

enough mist to grow at rates comparable to roots grown in liquid

culture. At higher packing fractions, on the other hand, the

opposite appeared to be true – roots grew more rapidly.

In the mist

deposition model (Wyslouzil et al., 1997), root beds are treated

as if they are fibrous filters. For a fixed droplet size Dp,

the droplet capture efficiency (hB)

of the root bed is given by

hB

= 1-exp[(-4LahC)

/ (DR(1-

a))],

where α is the packing fraction, L is the length

of the root bed, DR is the diameter of the

root and

hC

is the combined capture efficiency due to impaction and

interception (hIMP+INT),

and diffusion (hD),

and these efficiencies are all functions of Dp

(Crawford, 1976; Friedlander 1977). The overall mass deposition

efficiency (hOM)

of the root bed is the product of the root bed efficiency

hB(DPi)

and the mass fraction m(DPi) of mist

particles of diameter DPi, summed over the

aerosol size distribution data:

hOM

= ∑ihB(DPi)

× m(DPi). Finally, the medium captured

by the roots (Vdep, mL d-1) is

expressed as: Vdep = 24w

× QL ×

hOM,

where the factor of 24 converts from hr to d,

w

is the duty cycle (min hr-1), and QL

is the medium flow rate (mL min-1) during the mist

“on” cycle. The model is valid only when the flow rate is low

and the Reynold’s number (Re), based on the root diameter, is <

10 (Wyslouzil et al., 1997).

The medium

required to support the growth of roots (Vreq,,

mL d-1), in turn, depends on the amount of biomass

present, its growth rate

m

(d-1), the apparent biomass yield of the

growth-limiting nutrient YX/S (g DW biomass

per g nutrient consumed) and the concentration of the limiting

nutrient in the medium CS (g L-1).

To maintain a desired growth rate,

m,

Vdep ≥ Vreq. Kim et al.

(2002) suggested that at low packing fractions a lack of

nutrients was likely limiting A. annua hairy root growth

in the mist bioreactor. Since Vdep is a strong

non-linear function of

a,

increasing

a

rapidly increases Vdep thereby supporting a

higher growth rate because the roots are now capturing more

nutrients. Although Vreq also depends on

a,

that relationship is linear. Kim et al. (2002) showed that Vdep

can be greater than Vreq, but depends on the

nutrient concentration, as well as the growth rate and diameter

of the roots.

LAB SCALE

STUDIES

Exploiting

the Mist Deposition Model to Improve Root Growth in Mist

Reactors

The mist

deposition model suggested several ways to improve the growth

rate of roots in a mist reactor beyond that observed by Kim et

al. (2002). First, increasing the initial biomass density

(packing fraction, a) should increase the droplet capture

efficiency of the roots and better satisfy the biological

demand. Second, increasing the total carbon available to the

roots, either by increasing the sugar concentration (CS) of the

medium or by increasing the mist duty cycle (w), should also

increase the growth rate. To test these hypotheses, Towler et

al. (2007) constructed a small mist reactor (0.05 L growth

chamber) and conducted an extensive number of short (6 day) root

growth experiments.

As

illustrated in Figure 2, the measured growth rates of 0.12 d-1

over a 6-day period at initial packing fractions in the small

mist reactor ranging from 0.19-0.39. In the work of Kim et al.

(2002), packing fractions were no more than 0.056 when mist mode

commenced and the growth rate (m)

was ~ 0.07 d-1 (points at

a

<0.1 in Figure 2). The work by Towler et al. (2007), confirmed

that a higher initial inoculum density does positively affect

root growth in mist reactors.

Figure 2.

Hairy root growth vs. packing fraction, α, in mist reactors.

To test the

limits of packing density that can be achieved in a mist

reactor, roots were grown in the small mist reactor from an

initial α of 0.39 for 10.3 days. Although the average

growth rate was only 0.11 d-1, the final α was

0.71, and, as illustrated in Figure 3, the harvested roots

appeared non-necrotic and healthy throughout the dense bed. In

liquid-phase culture such high biomass densities are difficult

to achieve because at tissue concentrations approaching 10-40 g

DW L-1 (a range of α ~ 0.20-0.80) the root bed

resists fluid flow resulting in too high a pressure drop

(Carvalho and Curtis, 1998; Ramakrishnan and Curtis, 2004) with

a liquid flow resistance similar to a column of packed sand

(Carvalho and Curtis, 1998; Nield and Bejan, 1991).

Figure 3.

Roots removed from small mist reactor. Final packing density =

0.71; root bed diameter is 2.7 cm. Upper panel is side view;

lower panel is cross sectional view of roots half way down the

height of the bed.

Besides the

packing density, α, one of the other key components of

the mist deposition model is the nutrient concentration, CS.

To grow at a particular growth rate, µ, the

volume of medium required by the roots, Vreq,

is inversely proportional to CS. Increasing

CS should, therefore, increase µ at fixed

Vdep, or decrease Vreq at

fixed µ. Towler et al. (2007) tested this hypothesis

using the small (0.05 L) mist reactor. A. annua hairy

roots were fed medium containing 3% or 5% sucrose at a standard

mist duty cycle (15 min on, 15 min off). After 6 days, roots

grown with 5% sucrose had significantly more biomass than roots

grown with 3% sucrose (Table 3), while the highest growth rate

occurred at day 4. The growth rate at day 4 with 5% sucrose in

the mist reactor is equivalent to that in shake flasks. Although

we have tried to grow roots in shake flasks at α values

equivalent to what we used in the small mist reactor, there was

little to no growth (Towler, 2005). Taken together these results

corroborate the mist deposition model’s (Wyslouzil et al., 1997)

prediction that at lower root bed packing densities (α ≤ 0.1)

roots cannot capture all of the droplets. Thus, especially in

the early stages of operation (just after inoculation), media

with a higher sucrose concentration must be provided to deliver

adequate levels of carbon to achieve and sustain a high growth.

Although most of the droplets are captured once α reaches ~ 0.2,

maintaining high growth rates in these densebeds also requires

maintaining a high sucrose concentration to feed the dense root

population.

Table 3.

Sugar concentration increases growth in mist bioreactors after 4

and 6 days. Initial DW of inoculum was 8 g FW L-1

(0.52 g DW L-1).

|

Growth Condition

(working volume) |

DW (g) |

µ (d-1) |

|

Mist reactor (35 mL) |

4 d |

6 d |

4 d |

6 d |

|

3% sucrose |

1.11 |

1.22 |

0.16 |

0.12 |

|

5% sucrose |

1.29 |

1.77 |

0.20 |

0.13 |

|

Shake flasks (50 mL) |

|

|

|

|

|

3% sucrose |

0.05 |

0.07 |

0.15 |

0.17 |

|

5% sucrose |

0.06 |

0.08 |

0.19 |

0.18 |

An

alternate method for providing more nutrients to root cultures

in a mist reactor is to increase the misting duty cycle,w

(min hr-1) which increases the medium flow rate, QL,

(mL min-1), and thus, the total delivery of nutrients

to the roots. The mist duty cycle, however, can significantly

affect the growth rate of roots in a mist bioreactor (Towler et

al., 2006; Liu et al., 1999) with some evidence of species

specificity (DiIorio et al., 1992b). Recent experiments by

Towler et al. (2007) separated the effect of duty cycle from

concurrent changes in the sugar deposition rate. By varying the

mist duty cycle and the sucrose concentration together so that

the average sugar deposition rate was constant, they showed that

alteration of the mist duty cycle had no significant effect on

A. annua root growth. In contrast, when different sugar

concentrations were fed using the same misting cycle, then

growth increased as sugar concentration increased (Towler et

al., 2007). Taken together these studies showed that α

and CS are the two most important factors to

optimize in order to achieve high growth rates of hairy roots in

mist reactors.

Other

Factors Affecting Root Growth in Mist Reactors

Besides

α, CS , and

w

from the mist deposition model, other factors have been observed

to affect root growth in mist reactors including mist flow

orientation, inoculum distribution, gas composition, medium

“conditioning” factors, and medium preparation methods. Mist

reactors that are fed from the top down have the advantage of

co-current down-flow of gas and liquid phases along with gravity

and this facilitates drainage. If mist is provided from the

bottom up, coalescence is greatest on the roots closest to the

mist feed so less mist reaches tissues in the top layers of the

growth chamber (Liu et al., 1999). With increasing root

bed density, the lower regions will likely become waterlogged if

mist is provided upwards. Indeed using upflow mist delivery

(Chatterjee et al., 1997) resulted in root necrosis in A.

annua a condition that was never observed with downflow mist

delivery (Wyslouzil et al., 2000). It is also likely that as the

root bed becomes very dense, the lower sections will accumulate

even more liquid and essentially become submerged.

If the root

inoculum is not evenly distributed within the growth chamber of

a mist reactor, a large percentage of the mist will exit the

chamber without contacting any roots. Furthermore, roots that

capture mist droplets will probably grow rapidly and

subsequently form dense root clusters. Most mist reactors have

been inoculated by first flooding the growth chamber with media,

adding the roots, and then running the reactor as a bubble

column until the roots immobilize onto a trellis.

Like roots

of whole plants, hairy roots also respond to changes in gas

composition with their response varying with plant species.

Besides oxygen most other gas studies have focused mainly on CO2.

Air enriched with CO2 enhanced growth by decreasing

the lag time in some root cultures (30), but not in others

(Wyslouzil et al., 2000; Kim et al., 2002). If CO2 is

observed to stimulate hairy root growth for a species under

study, it is important not to overaerate a root bed in a mist

reactor to avoid purging beneficial gases. Alternatively, the

ability to provide a controlled amount of CO2

enriched air to root beds is one of the design benefits of using

a mist reactor. The effect of changing the combined levels of O2,

CO2, or C2H4 has not, however,

been studied to date.

Reactors

can be operated in a batch mode where coalesced mist culture

medium is collected and recycled back into the reservoir after

exiting the growth chamber. They can also be run in a continuous

mode whereby the culture medium only passes over the tissue once

prior to being discarded, and fresh medium is continuously added

to the reservoir. Although the latter supplies fresh medium and

would be expected to stimulate growth, usually it does not

because roots often prefer “conditioned” medium. Conditioned

medium is produced by growing roots in fresh media for up to 2

weeks (Wyslouzil et al., 2000) during which time they adjust the

pH and distribution of nutrients. Roots also exude growth

stimulating compounds including oligosaccharides (Schroder et

al., 1989), peptides (Matsubayashi et al., 1996), and auxins

(Weathers et al., 2005). Conditioned medium can easily be

introduced into the medium reservoir by filter sterilization.

Most

reactor studies use medium prepared by autoclaving. During this

process however, the sucrose in the medium is partially

hydrolyzed to fructose and glucose, and small amounts of toxic

byproducts are produced (Weathers et al., 2004) resulting in an

undefined medium. Such variations can lead to aberrations in

hairy root growth (Kim et al., 2002) and secondary metabolite

production (Kim et al., 2002; Weathers et al., 2004) in both

liquid and gas-phase culture systems. Use of filter sterilized

medium eliminates such problems.

SCALING UP

MIST/SPRAY REACTORS

Despite

many lab scale studies, there have been few in depth studies on

scaling up mist or spray reactors for hairy root cultures. One

early study at 500 L used a series of hanging hooks to

immobilize Datura roots that were then grown for 40 days

(Wilson, 1997). Productivity, however, was low at 1.3 g DW L-1

d-1 with a final packing density of about 8% (α

= 0.08; FW V-1). Three more recent studies had

more productive growth yields (Williams and Doran, 2000;

Ramakrishnan and Curtis, 2004; Huang and Chou, 2006), and the

key elements of those studies are summarized in Table 4. In

contrast to the fine mists (droplets~10 µm) used by the Weathers

and Liu labs (Table 2), the studies shown in Table 4 used

sprays, with median volume droplet diameters exceeding 50 µm.

Williams and Doran (2000) concluded that their spray reactor was

not effective because as the biomass density of the root bed

increased the large droplets resulted in the root bed becoming

water logged and gas exchange plummeted. Indeed Ramakrishnan and

Curtis et al. (2004) noted that in their spray reactor large

amounts of interstitial liquid accumulated, and they needed to

enrich the aeration gas with oxygen to maintain growth.

Furthermore, the liquid feed rate (L d-1) in these 3

studies often exceeded the volume of the culture vessel further

aggravating liquid accumulation. For example, in a 14 L

vessel Ramakrishnan and Curtis (2004) provided 648 L d-1

of liquid media to a maximum of 752 g FW of roots (Table 4).

They initiated their reactors in a liquid bubble column mode for

~12 d, shifted to trickle bed mode for the next 8-9 d to enhance

aeration, and eventually enriched the air to 37% O2

in order to maintain high growth rates during the last 5 days of

culture. Only then were they able to achieve a final high yield

of root biomass (Ramakrishnan and Curtis, 2004).

Although

the 14 L trickle bed reactor run by Ramakrishnan and Curtis

(2004) reached a final

a

= 0.75

(Table 4), the growth rate was 0.13 d-1 without

oxygen enrichment and 0.21 d-1 with oxygen

enrichment. In contrast their scaled-down (1.6 L) version of

that reactor yielded a higher growth rate of 0.35 - 0.40 d-1

for the first 4 days. Unfortunately, throughout the rest of the

culture period the growth rate steadily declined to < 0.10 d-1.

The small fine mist droplet reactor used by Towler et al. (2007)

was much smaller (0.05 L), yet a biomass density comparable to

that obtained by Ramakrishnan and Curtis (2004) was attained

with an

a

= 0.71

and overall growth rate of 0.11 d-1.

This was,

however, achieved without addition of extra O2 or

other nutrients (Towler et al., 2007). The 1.6 L trickle bed

reactor (Ramakrishnan and Curtis, 2004) had a biomass/medium

ratio about 8´ greater and a bed depth about 5´ deeper than the

small mist reactor of Towler’s, never the less the high packing

density obtained in the small mist reactor substantiates the

importance of droplet size and total liquid throughput in gas

phase reactors. Clearly, however, more equitable performance

comparisons must be made to determine the potential of larger

scale mist reactors.

In mist

reactors, therefore, it is critical to keep droplet diameter

small and liquid throughput must not exceed levels that result

in water logging of the culture. If the latter occurs, then a

mist reactor reverts to a liquid-phase reactor. In the mist

reactor high-density root beds grow faster than low density

beds, because high-density beds capture media droplets more

efficiently (Towler et al., 2007). This counterintuitive

reactor, however, poses a challenge to scale-up because the high

inoculum levels required to create a dense root bed in a mist

reactor quickly become impractical as the reactor volume

increases. Taken together it is clear that gas-phase reactors

must be carefully designed, studied, and operated to achieve the

high growth yields that we (Towler et al., 2007), and others

(Suresh et al., 2005; Ramakrishnan and Curtis, 2004), have

observed.

CONCLUSIONS

AND FUTURE RECOMMENDATIONS

Mist and

other gas-phase reactors clearly offer some significant benefits

for culturing hairy roots, including lack of oxygen stress,

rapid growth, and production of high yields and, sometimes, of

new secondary metabolites. Scaling up these reactors however,

presents some unique challenges. For example, what is the

volumetric limit of a mist reactor? How does root morphology

alter performance of a reactor? Do thick hairless roots grow

more effectively than thin hairy ones? The mist deposition model

(Wyslouzil et al., 1997) suggests that may indeed be the case.

If so, how does one engineer a reactor to accommodate variations

in root morphology? These types of questions along with others

need to be addressed before mist and other gas-phase reactors

become practical.

ACKNOWLEDGEMENTS

The authors

thank the following agencies for funding some of the described

work: DOE P200A50010-95, NSF BES-9414858, USDA 93-38420-8804,

and NIH 1R15 GM069562-01.

Table 4.

Comparisons between three recently scaled-up gas-phase hairy

root reactors.

|

Reactor parameters/Results |

Huang & Chou (2006) |

Ramakrishnan & Curtis (2004) |

Williams & Doran (2000) |

|

Plant species |

Stizolobium hassjoo |

Hyoscamus muticus |

Atropa belladonna |

|

Working vol (L) |

9 |

14 |

4.4 |

|

Aspect ratio |

2.1 |

6.0 |

1.7 |

|

Median drop diameter (µm)

1 |

> 50 |

> 150 |

> 50 |

|

Medium flow (L min-1) |

0.12 |

0.45 |

0.13 |

|

Misting cycle |

1 hr on:1 hr off |

continuous |

continuous |

|

Gas flow (vol gas/working vol/ min (vvm)) |

0.022 |

~ 0.7 |

0.27 |

|

Inoculum (g DW L-1) |

0.15 (est) |

0.2 |

0.18 (est) |

|

Final yields (g): FW L-1

α

DW L-1 |

83 (est)

0.083

6.95 |

752

0.752

36 |

182 (est)

0.182

11.23 (est) |

|

µ

(d-1) [run length in days] |

0.20 (est) [16] |

0.21 [25] |

0.16 (est) [24.9]

0.08 (est) [41.8] |

|

Notes |

countercurrent dual misting |

cocurrent gas/liquid |

cocurrent gas/liquid |

REFERENCES

CITED

Atkinson B,

Mavituna F (1991) Biochemical Engineering and Biotechnology Handbook,

Ed 2. Macmillan, Basingstoke, UK, pp 703-705

Bais HP, Suresh

B, Raghavarao KSMS, Ravishankar GA (2002) Performance of hairy root

cultures of Cichorium intybus L. in bioreactors of different

configurations. In Vitro Cell Dev Biol Plant 38: 573-580

Carvalho EB,

Curtis WR (1998) Characterization of fluid-flow resistance in root

cultures with a convective flow tubular bioreactor. Biotechnol

Bioeng 60:375-384

Chatterjee C,

Correll MJ, Weathers PJ, Wylslouzil BE, Walcerz DB (1997) Simplified

acoustic window mist bioreactor. Biotechnol Techniq 11:155-158

Correll MJ, Wu

Y, Weathers PJ (2001) Controlling hyperhydration of carnations (Dianthus

caryophyllus L.) grown in a mist reactor. Biotechnol Bioeng

74:307-314

Correll MJ,

Weathers PJ (2001) Effects of light CO2, and humidity on

carnation growth, hyperhydration, and cuticular wax development in a

mist reactor. In Vitro Cell Develop Biol Plant 37:405-413

Correll MJ,

Weathers PJ (2001) One-step acclimatization of plantlets using a

mist reactor. Biotechnol Bioeng 73:253-258

Crawford M

(1976) Air Pollution Control Theory. McGraw-Hill, NY, NY, pp 424-433

Cuello JL,

Walker PN, Curtis WR (2003) Design of ebb-and-flow bioreactor (EFBR)

for immobilized “hairy root” cultures: Part I. Preliminary design

models and culture parameters. Transactions ASAE 46:1457-1468

Curtis WR

(1993) Cultivation of roots in bioreactors. Curr Opin Biotechnol

4:205-210

Curtis WR

(2000) Hairy roots, bioreactor growth. In RE Spier, ed, Encyclopedia

of Cell Biotechnology, John Wiley and Sons, NY, NY, pp 827-841

DiIorio AA,

Cheetham RD, Weathers PJ (1992a) Carbon dioxide improves the growth

of hairy roots cultured on solid medium and in nutrient mists. Appl

Microbiol Biotechnol 37:463-467

DiIorio AA,

Cheetham RD, Weathers PJ (1992b) Growth of transformed roots in a

nutrient mist bioreactor: reactor performance and evaluation. Appl

Microbiol Biotechnol 37:457-462

Flores HE,

Medina-Bolivar F (1995) Root culture and plant natural products:

unearthing the hidden half of plant metabolism. Plant Tiss Cult

Biotechnol 1:59-74

Friberg JA,

Weathers PJ, Gibson DG (1992) Culture of amebocytes in a nutrient

mist bioreactor. In Vitro Cell Develop Biol 28A:215-217

Friedlander SK

(1977) Smoke, Dust and Haze: Fundamentals of Aerosol Behavior,

Wiley, NY, NY, p 338

Geankopolis CJ

(1993) Transport Processes and Unit Operations, Ed 3,

Prentice-Hall, Englewood Cliffs, NJ, pp 586-587

Guillon S,

Trémouillaux-Guiller J, Pati PK, Rideau M, Gantet P (2006)

Harnessing the potential of hairy roots: dawn of a new era. Trends

in Biotechnol 24:403-409

Hallard D,

Geerlings A, van der Heijden R, Lopes Cardoso MI, Hoge JHC,

Verpoorte R (1997) Metabolic engineering of terpenoid indole and

quinoline alkaloid biosynthesis in hairy root cultures. In PM Doran,

ed, Hairy Roots: Culture and Applications. Harwood Academic

Publishers, Amsterdam, The Netherlands, pp 43-49

Huang SY, Hung

CH, Chou SN (2004) Innovative strategies for operation of mist

trickling reactors for enhanced hairy root proliferation and

secondary metabolite productivity. Enz Microb Technol 35:22-32

Huang SY, Chou

SN (2006) Elucidation of the effects of nitrogen source on

proliferation of transformed hairy roots and secondary metabolite

productivity in a mist trickling reactor by redox potential

measurement. Enz Microb Technol 38:803-813

Kim YJ (2001)

Assessment of bioreactors for transformed root cultures. PhD thesis,

Worcester Polytechnic Institute, Worcester, MA

Kim Y,

Wyslouzil BE, Weathers PJ (2001) A comparative study of mist and

bubble column reactors in the in vitro production of

artemisinin. Plant Cell Rep 20:451-455

Kim YJ,

Weathers PJ, Wyslouzil BE (2002) Growth of Artemisia annua

hairy roots in liquid and gas-phase reactors. Biotechnol Bioeng

80:454-464

Kim YJ,

Wyslouzil B, Weathers J (2002) Secondary metabolism of hairy roots

in bioreactors. In Vitro Cell Develop Biol Plant 38:1-10

Kim YJ,

Weathers PJ, Wyslouzil BE (2003) Growth dynamics of Artemisia

annua hairy roots in three culture systems. Biotechnol Bioeng

83:428-443

Lang RJ (1962)

Ultrasonic atomization of liquids. J Acoust Soc A 34:6-8

Liu CZ, Wang

YC, Zhao B, Guo C, Ouyang F, Ye HC, Li GF (1999) Development of a

nutrient mist bioreactor for growth of hairy roots. In Vitro Cell

Dev Biol Plant 35:271-274

Matsubayashi Y,

Sakagami Y (1996) Phytosulfokine, sulfated peptides that induce the

proliferation of single mesophyll cells of Asparagus officinalis

L. Proc Natl Acad Sci USA 93:7623-7627

Mahagamasekera,

MGP, Doran, PM (1998) Intergeneric co-culture of genetically

transformed organs for the production of scopolamine. Phytochemistry

47:17-25

McKelvey SA,

Gehrig JA, Holar KA, Curtis WR (1993) Growth of plant root cultures

in liquid- and gas-dispersed reactor environments.

Biotechnol Prog

9:317-322

Nield DA, Bejan

A (1992) Convection in porous media.

Springer-Verlag, NY, NY, pp 408

Nuutila AM,

Lindqvist AS, Kauppinen V (1997) Growth of hairy root cultures of

strawberry (Fragaria x. ananassa Duch.) in three different

types of bioreactors. Biotechnol Techn 11:363-366

Palazon J,

Mallol A, Eibl R, Lettenbauer C, Cusido RM, Pinol MT (2003) Growth

and ginsenoside production in hairy root cultures of Panax

ginseng using a novel bioreactor. Planta Med 69:344-349.

Perry RH, Green

DW (1997) Perry’s Chemical Engineer’s Handbook.

(McGraw-Hill, New York, NY), 7th Edition, pp. 14-62 –

14-69, 14-81 – 14-82.

Ramakrishnan D,

Curtis WR (2004) Trickle-bed root culture bioreactor design and

scale-up: growth, fluid-dynamics, and oxygen mass transfer.

Biotechnol Bioeng 88:248-260

Schroder R,

Gertner F, Steinbrenner B, Knoop B, Beiderbeck R (1989) Viability

factors in plant suspension cultures – some properties. J Plant

Physiol 135:422-427

Sharaf-Eldin M,

Weathers PJ (2006) Movement and containment of microbial

contamination in the nutrient mist bioreactor. In Vitro Cell Develop

Biol Plant 42:553-557

Souret FF,

KimYJ, Wyslouzil BE, Wobbe KK, Weathers PJ (2003) Scale-up of

Artemisia annua L. hairy roots cultures produces complex

patterns of terpenoid gene expression. Biotechnol Bioeng 83:

653-667

Sung LS, Huang

SY (2006) Lateral root bridging as a strategy to enhance L-DOPA

production in Stizolobium hassjoo hairy root cultures by

using a mesh hindrance mist trickling bioreactor. Biotechnol Bioeng

94:441-447

Suresh B, Bais

HP, Raghavarao KSMS, Ravishankar GA, Ghildyal NP (2005) Comparative

evaluation of bioreactor design using Tagetes patula L. hairy

roots as a model system. Proc Biochem 40:1509-1515

Tarr A, Zhu G,

Browner RF (1991) Fundamentals aerosol studies with an ultrasonic

nebuliser. Appl Spectrosc 45:1424-1432

Towler MJ (2005) Effects of inoculum density, carbon concentration,

and feeding scheme on the growth of transformed roots of

Artemisia annua in a modified nutrient mist bioreactor. PhD

thesis,

Biology and Biotechnology Worcester Polytechnic Institute,

Worcester, MA

Towler MJ, Kim

Y, Wyslouzil BE, Correll MJ, Weathers PJ (2006) Design,

development, and applications of mist bioreactors for

micropropagation and hairy root culture. In SD Gupta, Y Ibaraki,

eds, Plant Tissue Culture Engineering, Springer, The Netherlands, pp

119-134

Towler MJ,

Wyslouzil BE, Weathers PJ (2007) Using an aerosol

deposition model to increase hairy root growth in a mist reactor.

Biotechnol Bioeng 96:881-891

Weathers PJ,

Giles KL (1988) Regeneration of plants using nutrient mists. In

Vitro Cell Develop Biol Plant 24:727‑732

Weathers PJ,

Giles K, inventors (1989) Mist cultivation of cells. U.S. Patent

#4,857,464 and other International Patents (European, Israeli,

Australian, Canadian, New Zealand)

Weathers PJ,

Cheetham RD, Giles KL (1988) Dramatic increases in shoot number and

length for Musa, Cordyline, and Nephrolepis using

nutrient mists. Acta Hortic 230:39‑43

Weathers PJ,

Zobel RD (1992) Aeroponics for the culture of organisms, tissues,

and cells. Biotechnol Adv 10:93-115

Weathers PJ,

Bunk G, McCoy M (2005) The effect of phytohormones on growth and

artemisinin production in Artemisia annua hairy roots. In

Vitro Cell Devel Biol Plant 41:47-53

Weathers PJ,

DeJesus-Gonzalez L, Kim YJ, Souret FF, Towler MJ (2004) Alteration

of biomass and artemisinin production in A. annua hairy roots

by media sterilization method and sugars. Plant Cell Rep 23:414-418

Weathers PJ,

Wyslouzil BE, Wobbe KK, Kim YJ, Yigit E (1999) Workshop on

bioreactor technology. The biological response of hairy roots to O2

levels in bioreactors. In Vitro Cell Develop Biol Plant 35:286-289

Weathers PJ,

Wyslouzil BE (2007) Alternate bioreactors: Mist. In R.E. Spier, eds,

Encyclopedia of Cell Technology, Ed 2, John Wiley & Sons, NY, NY, In

press

Weathers PJ,

Zobel RD (1992) Aeroponics for the culture of organisms, tissues,

and cells. Biotechnol Adv 10:93-115

Whipple M

(1995) Deposition of Nutrient Mist onto Hairy Root Cultures,

M.S. Thesis, Chemical Engineering, Worcester Polytechnic Institute,

Worcester, MA

Whitney PJ

(1990) Novel bio-reactors for plant root organ cultures. Abstracts

VII Intl. Cong. Plant Tissue Cell Cult, Amsterdam, The Netherlands;

Abstract C4-19, p 342

Whitney P

(1992) Novel bioreactors for the growth of roots transformed by

Agrobacterium rhizogenes. Enz Microbiol Technol 14:13-17

Williams GRC,

Doran PM (2000) Hairy root culture in a liquid-dispersed bioreactor:

characterization of spatial heterogeneity. Biotechnol Prog 16:391-401

Wilson PDG

Hilton MG Meehan PTH Waspe CR Rhodes MJC (1990) The cultivation of

transformed roots from laboratory to pilot plant. In HJJ Nijkamp,

LHW van der Plas, J van Aartrijk, eds, Progress in Plant Cellular

and Molecular Biology, Kluwer Academic Publishers, Dordrecht, The

Netherlands, pp 700-705

Wilson DG

(1997) The pilot-scale cultivation of transformed roots. In PM

Doran, ed, Hairy Roots: culture and applications, Gordon and

Breach/Harwood Academic, UK, pp 179-190

Wyslouzil BE,

Waterbury RG, Weathers PJ (2000) The growth of single roots of

Artemisia annua in nutrient mist bioreactors. Biotechnol Bioeng

70:143-150

Wyslouzil BE,

Whipple M, Chatterjee C, Walcerz DB, Weathers PJ, Hart DP (1997)

Mist deposition onto hairy root cultures: aerosol modeling and

experiments. Biotechnol Prog 13:185-194

Wysokinska H,

Rozga M (1998) Establishment of transformed root cultures of

Paulownia tomentosa for verbascoside production. J Plant Physiol

152:78-83

Wysokinska H,

Chmiel A (1997) Transformed root cultures for biotechnology. Acta

Biotechnol 2:131-159

Zhang C,

Medina-Bolivar F, Buswell S, Cramer CL (2005) Purification and

stabilization of ricin B from tobacco hairy root culture medium by

aqueous two-phase extraction. J Biotechnol 117:39-48

Accepted for

publication: 7 October 2008

|